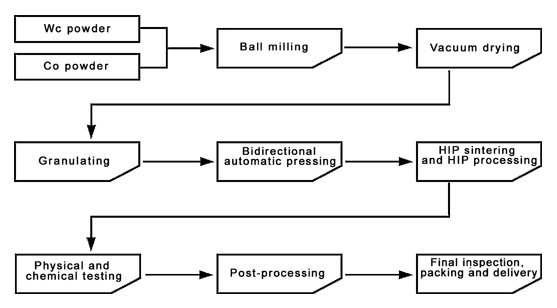

The production process for various grades of cemented carbide is basically the same, i.e. prepare powder burden powder mixing-pressing-sintering-post machining. Only some minor process parameter adjustments need to be done occasionally.

In the course of over 70 years of development and as basic theoretical research goes deeper internationally, carbide industry's equipment and technologies improved significantly. New technologies and equipment emerged in western countries in 1970s have become more and more popular in China's carbide manufacturing industry and are driving the development of carbide industry in China.

Powder mixing operation: Tumbling ball mill is gradually changing to blending ball mill, and roller screen granulation is gradually changing to spray granulation.

Pressing operation: As pressing machines become more precise, precision pressing has become the trend. Other new ways for forming carbide products are also emerged, such as vacuum extrusion and cold iso-static press, etc.

Sintering operation: The earliest method was to use hydrogen sintering furnace, and then, vacuum sintering and hot iso-static press furnace were adopted. The most revolutionary change was the emergence of sinter-HIP furnace, which made it possible to produce 100% dense carbide products.

Flow chart of cemented carbide manufacture